The Leading Manufacturer of

Friction Hinges and Torque Hinges

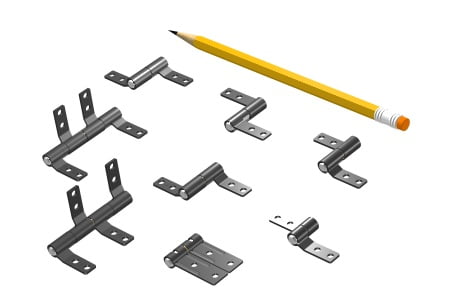

Friction Hinges

A friction hinge is a specialty hinge that holds a pivoting object in fixed position by providing resistance. Several standard friction hinge configurations are shown below that have been developed and fine-tuned over many years. We have chosen the most popular configurations and have organized them into families based on shaft diameter and housing style.

- Easily integrated into new designs

- No need for expensive tooling and development programs

SB-156 Friction Hinge Series

SB-188 Friction Hinge Series

SB-188 Series Type 2

ZE-188 Series

ZC-188 Series

SB-200 Friction Series

ZC-250 Series

Torque Ranges:

7 to 14 in.-lb.balanced

10 to 17 in.-lb. unbalanced

ZE-375 Series

Torque Ranges:

15 to 60 in.-lb. balanced

20 to 80 in.-lb. unbalanced

Torque Ranges:

18 inch-pound to 70 inch-pounds

MA-685 Series

Friction Hinge Features & Benefits

- Smooth, consistent feel over hinge lifetime

- 360-degree shaft rotation – pivot and stay put in any position

- All torque hinges meet and exceed life testing to 30,000 cycles

- No backlash, Minimal or no spring back

- Available in right- or left-hand configurations with additional corrosion protection available

- Balanced or Unbalanced Torque available on some models – specify the torque & torque direction required

- 100% product testing available – min / max and average torque

- Ability to mix and match housings & shafts / adapters to fit exact requirements

- > View Our Semi-Custom Hinge Capabilities

Friction Hinge Specifications

Features: TorqMaster hinges have no backlash or free play and minimal springback. Friction elements are spring steel. Corrosion protection is available. Please inquire regarding hinge conductivity. All shafts rotate 360 degrees. All hinges feature constant torque over life (30,000-plus cycles typical). TorqMaster hinges are assembled from inventory for fast delivery with no tooling charges.

* All TorqMaster friction hinges are available in balanced (same torque in both directions) or unbalanced (higher torque in one direction with approximately 35% less in other direction) and in left and right hand configurations (mirror image of shaft exiting housing)

What is A Friction Hinge?

A friction hinge, or torque hinge, is a specialty hinge that gives resistance to the pivoting motion. These hinges are typically used to control motion or hold a pivoting object opened or closed. The most common and relatable application is that of a “laptop hinge”. These motion control hinges are also known as:

A friction hinge, or torque hinge, is a specialty hinge that gives resistance to the pivoting motion. These hinges are typically used to control motion or hold a pivoting object opened or closed. The most common and relatable application is that of a “laptop hinge”. These motion control hinges are also known as:

- Free position hinge

- Positioning hinge

- Torque hinge

- Constant torque hinge

- Friction clutch

- Free-stop hinge

- Stop hinge … if designed with an added torsion spring they are also called counterbalanced hinges or equilibrated hinges.

How Does A Friction Hinge Work?

Friction hinges achieve their function by engineering the specific tolerances between the mechanical components. Additional material such as springs and lubricant are often employed to achieve the desired degree of resistance or damping to the hinge movement.

In some cases, the goal is for the object on the hinge to close completely at a desired degree of speed. In others, the torque is used to hold one or both objects to which the hinges are secured to in a specific position, not necessarily on a fully opened or closed position. When used to hold one of the pivoting members in place, they are designed to be moved by a force of a specific amount of torque greater than its rated torque.

Friction hinges are often customized or custom designed to meet the exact torque requirements of critical applications. Custom designs can provide one-way hinges, in which all the resistance is only in one direction; two-way hinges that have equal damping in both directions, or a combination of both. Design variables include lubricant viscosity, construction material, and degree of space tolerance between components to meet specific applications, such as medical, rugged, high or low temperature, or hazardous environments.

Applications

Friction hinges are used in a variety of applications where resistance is required. As mentioned earlier, one of the most popular applications is a laptop. The hinges allow the laptop screen to remain positioned exactly where you set it. They are also found in electronics devices used for medical, automotive, aerospace and defense. These hinges can be found in many transportation settings including planes, trains, boat and automobiles. Friction hinges are used in many other industrial and consumer applications from kitchen appliances to retail displays. Please click here if you’d like to learn more about friction hinge applications.

Stock & Custom Friction Hinges

TorqMaster designs and manufactures Friction Hinges in various sizes and strengths. The majority of our designs are 360-degree hinges, meaning that the hinge components can rotate about themselves all the way around. The motion is usually limited by the mating components to which the hinge is mounted.

TorqMaster designs and manufactures Friction Hinges in various sizes and strengths. The majority of our designs are 360-degree hinges, meaning that the hinge components can rotate about themselves all the way around. The motion is usually limited by the mating components to which the hinge is mounted.

Pioneering hinge design in some of the earliest portable computers, TorqMaster has provided standard and custom configurations to many leading manufacturers over many decades.

We manufacture and deliver hinge designs that all feature long and stable cycle life. Our selection includes a wide range of size and styles that are easily mounted and installed.

Many of our hinges can be balanced – having the same resistance to motion in both directions – or unbalanced (asymmetrical) with the force to produce movement 30% less in one direction. We even have “one-way” designs where the torque in one direction is negligible compared to the torque in the other direction.

With plating and painting options to enhance corrosion protection of our varying designs, our hinges are utilized in many applications across a variety of industries.

Why Choose TorqMaster for Your Friction Hinge Needs?

- Designing and manufacturing hinges is our only business for over 40 years

- We can handle short runs as low as 50 a month, or large runs in excess of 100,000 hinges per month

- We are passionate about quality – certified to ISO 9001:2015 (Certificate No. 9985QMS001)

- All hinges are RoHS, REACH and Conflict Minerals Compliant.

- 100% testing and traceability

- We offer on-site fabrication of hinges with difficult geometry, thanks to our in-house complete machine shop

- Fast turn-around of sample runs

Please send or fax drawings of your project to our sales department. Our engineers will help you choose the appropriate hinge, torque and torque directions or detent options. Custom Hinges or variations of stock designs are available for higher volume OEM applications, however a semi-custom shaft in a standard housing can often solve many design challenges.